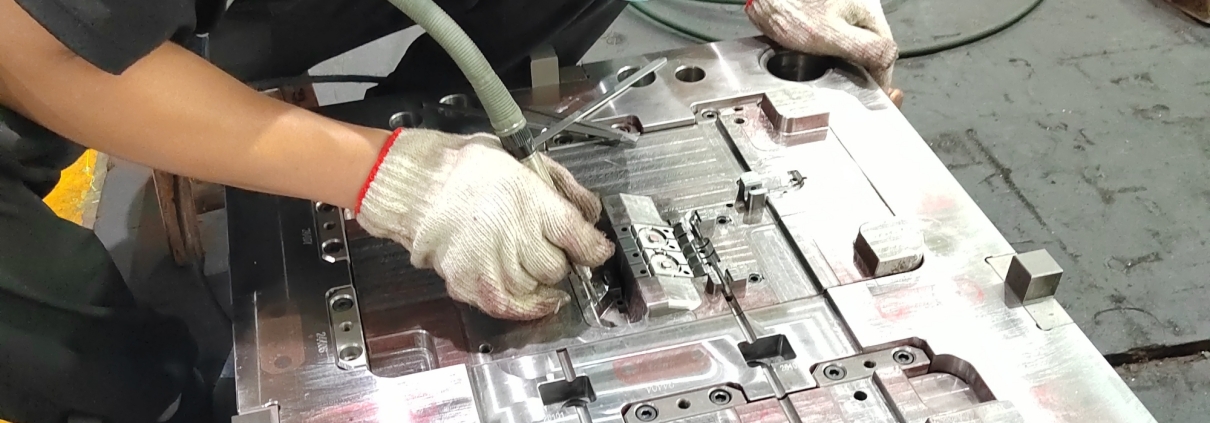

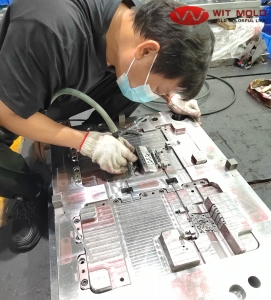

Skilled Toolmakers: The Key to High-Quality, Reliable Molds

At WIT Mold, our toolmakers are the cornerstone of our success. Equipped with years of hands-on experience and deep technical expertise, they combine professionalism, precision, and creativity to deliver molds that meet the highest standards. Each mold crafted by our toolmakers reflects meticulous attention to detail, ensuring tight tolerances, consistent performance, and exceptional durability.

Expertise That Ensures Consistency

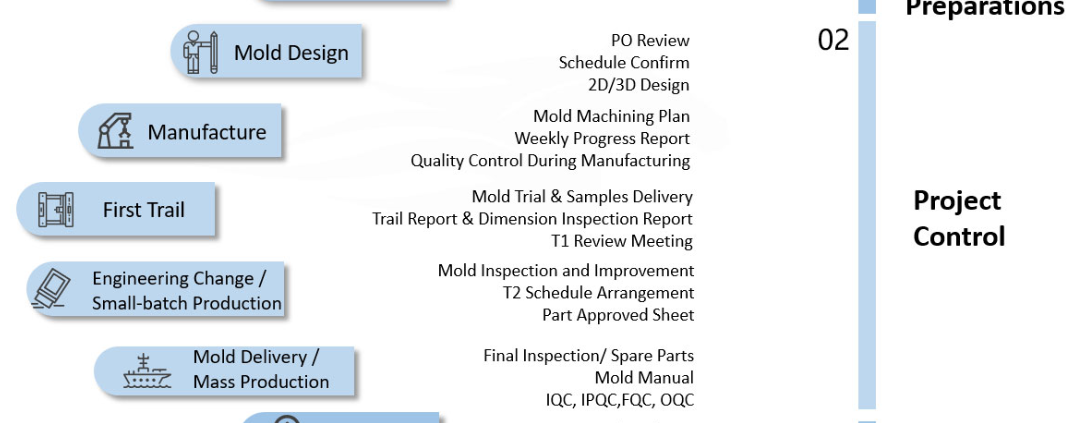

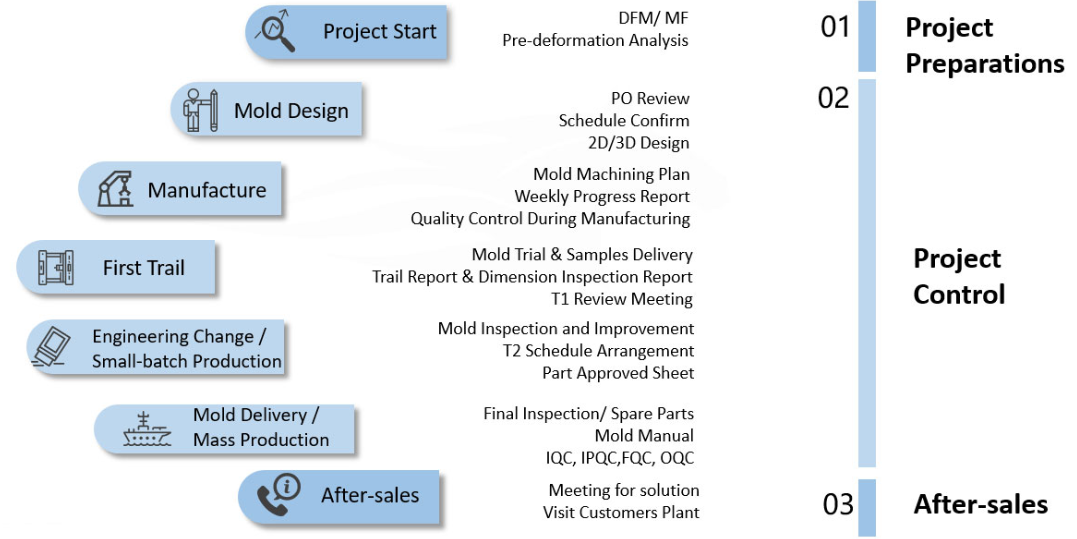

Our toolmakers’ skills go beyond technical proficiency—they are problem-solvers who anticipate potential challenges and optimize mold designs for manufacturability and long-term reliability. Their experience allows WIT Mold to consistently produce stable, high-quality molds, even for the most demanding specifications. This expertise is a key advantage that sets us apart in the mold manufacturing industry.

Combining Technology with Craftsmanship

WIT Mold leverages advanced CNC equipment alongside the unparalleled skills of our toolmakers. This combination allows us to execute complex projects with precision, ensuring every mold delivers superior performance. From the initial design phase to final shipment, our toolmakers are fully involved, guaranteeing that every step of production aligns with our strict quality standards.

Dedicated Professionals, Reliable Results

Our toolmakers are not just employees—they are dedicated professionals who form the foundation of WIT Mold’s reputation for excellence. Their commitment ensures that each mold is not only high-quality but also reliable and long-lasting. By prioritizing craftsmanship, experience, and innovation, WIT Mold continues to deliver exceptional molds that our customers can trust, project after project.