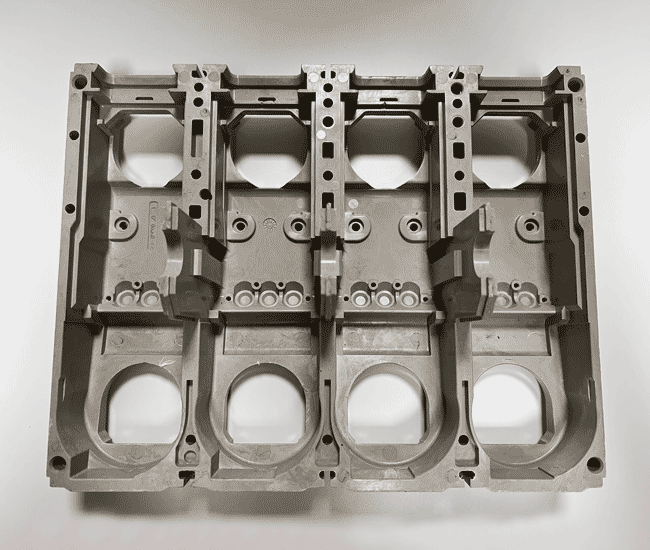

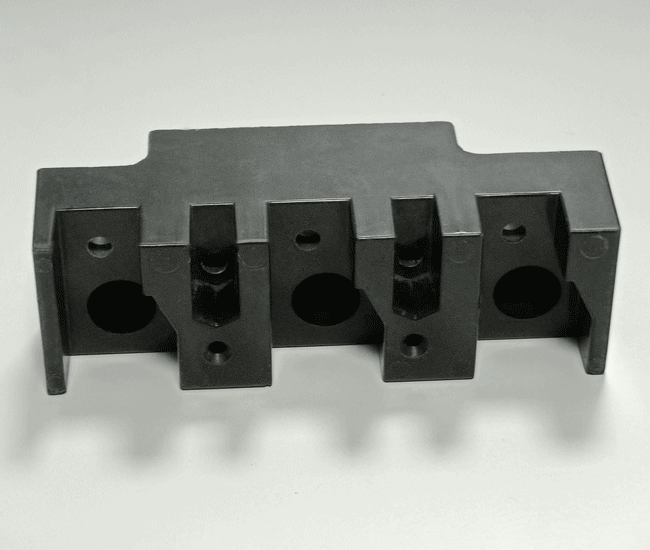

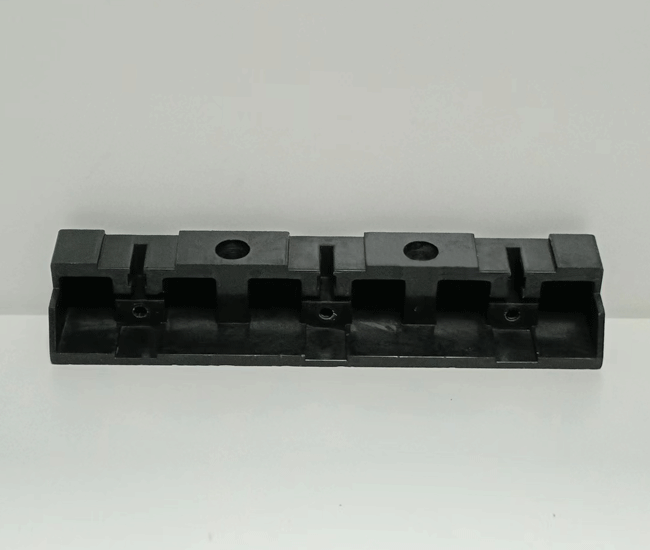

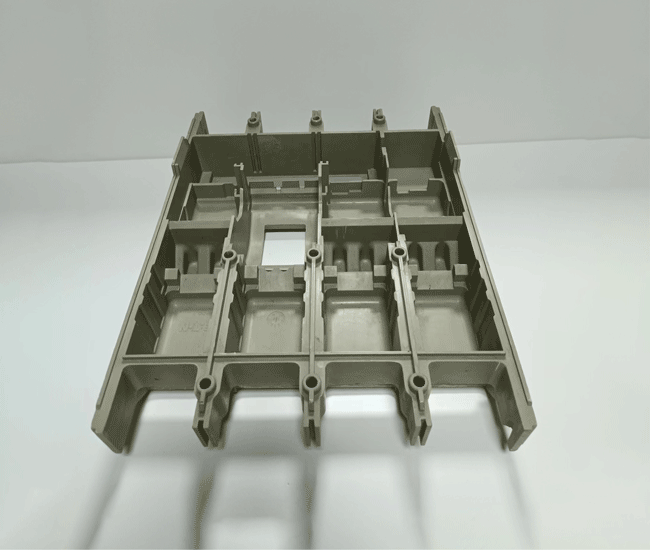

SMC COMPRESSION TOOLING

SMC molds, characterized by their high-strength and high-hardness construction using steel, boast polished surfaces that play a crucial role in ensuring the impeccable surface quality of the resultant SMC molded parts. The primary attribute defining SMC molds is their fabrication through a compression process, where the SMC material undergoes compression to attain its final form.

The distinctive production method involves the utilization of hydraulic presses for compression molding. In this process, the cavity and core of the mold are securely affixed to the upper and lower platens of the machine. The operational sequence initiates with the introduction of the SMC material into the open mold. Following this, the mold is meticulously sealed, subjected to a specific temperature, and the SMC material seamlessly flows throughout the entirety of the mold, driven by the synergistic forces of pressure and temperature.

In essence, the utilization of SMC molds, coupled with the precision of the compression process, ensures the creation of SMC molded parts that exhibit not only high-strength and hardness but also maintain a superior surface quality. The orchestration of these factors, facilitated by the hydraulic press and controlled temperature conditions, encapsulates the efficiency and reliability of the SMC molding technique.