Complete Guide to Injection Molding

Injection molding is one of the most widely used manufacturing processes for producing plastic parts. Whether you’re an engineer, designer, or business owner, understanding how injection molding works can significantly impact the quality, cost, and efficiency of your production process. Here’s a comprehensive guide to help you understand the ins and outs of injection molding.

What is Injection Molding?

Injection molding is a manufacturing process used to produce parts by injecting molten plastic into a mold cavity. The mold is then cooled, solidifying the plastic into the desired shape. This process allows for the high-volume production of complex and detailed parts, often used in various industries like automotive, medical, electronics, and consumer goods.

How Does Injection Molding Work?

The injection molding process involves several steps:

Injection: Plastic pellets are fed into a hopper, where they are heated until they melt. The molten plastic is then injected under high pressure into a mold cavity.

Cooling: After the mold is filled, the plastic is allowed to cool and solidify. The cooling time varies depending on the material, mold design, and part size.

Ejection: Once the part has solidified, the mold opens, and the part is ejected using ejector pins or other mechanisms.

Post-processing: After ejection, parts may undergo additional processes like trimming, painting, or assembly.

Types of Injection Molding

Several variations of injection molding are used depending on the material and product requirements:

Thermoplastic Injection Molding: Uses thermoplastic materials that soften when heated and harden when cooled. These materials can be reused and remolded multiple times.

Thermoset Injection Molding: Uses thermosetting plastics, which harden permanently after being heated. These materials cannot be remelted once they have set.

Multi-shot Injection Molding: Involves injecting different materials or colors in successive steps to create parts with multiple layers or different properties in a single cycle.Insert Molding: A process where metal inserts or other components are placed into the mold cavity before injection. The molten plastic encapsulates these inserts, creating a composite part.

Overmolding: A type of multi-shot molding that involves adding a layer of material over an existing part. This is commonly used for creating soft-touch grips or combining different materials into a single part.

Advantages of Injection Molding

High Precision: Injection molding can produce parts with tight tolerances, making it suitable for complex, intricate designs.

High Production Volume: Once the mold is created, large quantities of parts can be produced rapidly and efficiently.

Material Flexibility: A wide range of materials, including various types of plastics, can be used in injection molding.

Cost-Effective for Large Runs: While the initial cost of creating the mold can be high, the per-unit cost of parts decreases significantly with higher production volumes.

Complex Geometries: The process can create parts with complex shapes, undercuts, or even multi-material designs.

Common Materials Used in Injection Molding

The choice of material plays a crucial role in the functionality and durability of the final product. Some commonly used materials include:

Polypropylene (PP): Known for its flexibility, chemical resistance, and low cost, often used for packaging, automotive, and consumer goods.

Acrylonitrile Butadiene Styrene (ABS): Offers good impact resistance and strength, used in applications like automotive parts, toys, and electrical housings.

Polycarbonate (PC): A tough, high-performance plastic often used in applications requiring optical clarity or high strength, such as eyewear lenses and medical devices.

Nylon (PA): Known for its strength, wear resistance, and flexibility, often used in automotive, industrial, and consumer applications.

Polystyrene (PS): A rigid, low-cost plastic used for items like disposable cutlery, containers, and packaging.

Polyethylene (PE): A versatile and cost-effective material used in packaging, containers, and industrial applications.

Factors Affecting Injection Molding Process

Several factors can influence the quality and efficiency of the injection molding process:

Material Choice: The type of plastic material affects the temperature, viscosity, and cooling time, influencing cycle time and part quality.

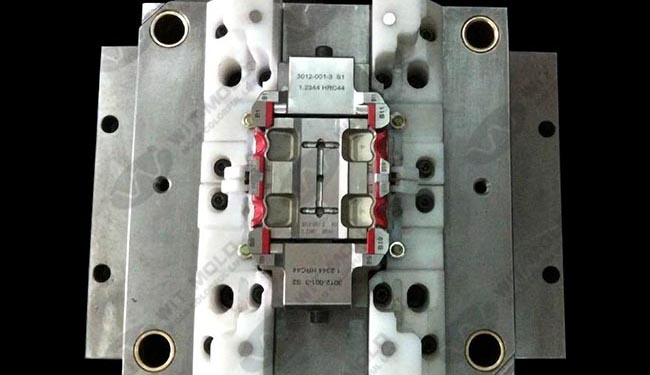

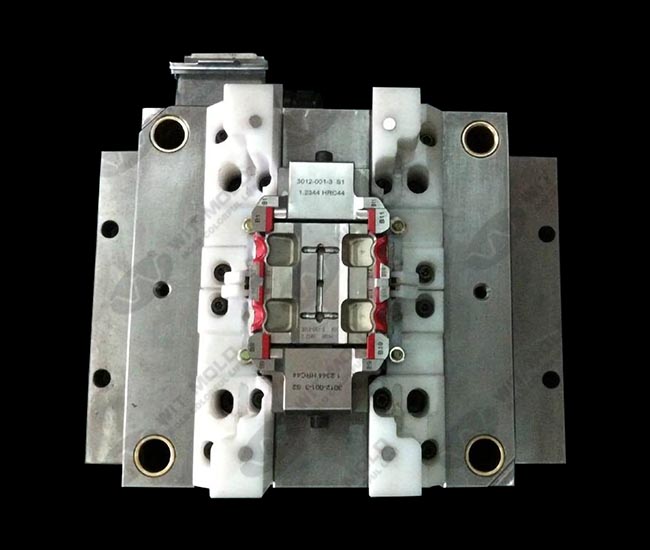

Mold Design: Proper mold design is critical to achieving high-quality parts. This includes factors such as gate placement, parting lines, cooling channels, and mold material.

Injection Speed and Pressure: The speed and pressure at which the plastic is injected into the mold affect the quality and consistency of the part.

Temperature Control: Maintaining the correct mold and material temperatures is crucial for ensuring uniform cooling and minimizing defects.

Cycle Time: The time required to complete one injection cycle influences production speed and cost efficiency.

Applications of Injection Molding

Injection molding is used in various industries for a wide range of products:

Automotive Parts: Dashboard components, bumpers, door panels, and air ducts.

Medical Devices: Syringes, diagnostic tools, surgical instruments, and device housings.

Consumer Electronics: Smartphone cases, TV housings, and computer parts.

Packaging: Containers, lids, bottles, and packaging inserts.

Toys and Games: Action figures, board game pieces, and playsets.

Household Goods: Kitchen tools, storage containers, and small appliances.

Limitations of Injection Molding

While injection molding offers many advantages, there are some limitations to consider:

High Initial Tooling Costs: Designing and creating the mold can be expensive, especially for complex parts.

Long Lead Times: Mold design and fabrication can take several weeks or even months, depending on the complexity.

Material Limitations: Not all materials are suitable for injection molding, and some may require special processing conditions.

Complexity of Design: While injection molding is great for complex shapes, there are still limitations to the type of geometries that can be achieved.

Conclusion

Injection molding is a powerful, efficient, and cost-effective process for producing high-quality plastic parts. Understanding the intricacies of the process, material choices, and mold design is key to optimizing production and ensuring the success of your project. Whether you’re creating a single prototype or a high-volume production run, mastering injection molding can help bring your design to life.

.jpg)