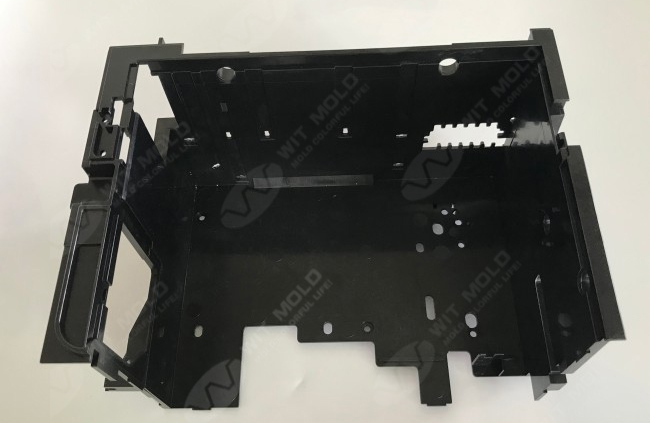

PVC injection molding is widely used for producing durable and versatile components, such as end caps, fittings, housings, and other custom parts. At WITMOLD, we specialize in high-quality PVC injection molding solutions that ensure precision, efficiency, and long-lasting performance. However, like any injection molding process, PVC molding can face defects that affect both functionality and aesthetics. Understanding these defects and implementing practical solutions is crucial for consistent product quality.

1. Warping

Warping occurs when a molded part twists or bends after ejection, often due to uneven cooling or variations in wall thickness. It is common in parts with long, thin sections or complex geometries. To prevent warping, maintaining uniform wall thickness and optimizing mold design are essential. At WITMOLD, we incorporate precise cooling channel layouts and carefully controlled packing pressure and holding times in our molds. This ensures even cooling and stable dimensions for every PVC end cap, reducing distortion and delivering high-quality, dimensionally accurate products.

2. Sink Marks

Sink marks are depressions or dimples that appear on thick sections of molded parts, often caused by uneven shrinkage or insufficient packing. They can compromise both the appearance and structural integrity of PVC components. At WITMOLD, we minimize wall thickness variation and use advanced mold flow simulation to predict and correct potential sink mark areas before production. By adjusting packing pressure, holding time, and melt temperature as needed, our molds consistently produce smooth, defect-free surfaces, even on complex end cap designs.

3. Flow Lines

Flow lines are streaks or patterns on the surface of molded parts caused by uneven material flow during injection. They usually result from improper injection speed, temperature variations, or sudden geometry changes. WITMOLD addresses these issues by optimizing injection parameters and designing molds for uniform PVC flow. Sharp corners and transitions are smoothed, and cooling systems are precisely controlled to ensure even filling. This approach eliminates flow lines and produces visually appealing, structurally sound PVC end caps.

4. Bubbles and Voids

Bubbles or voids occur when air or gas is trapped inside the part, weakening its structure and causing cosmetic defects. Moisture in PVC resin, insufficient mold venting, or excessive injection speed can all contribute to this problem. At WITMOLD, we carefully dry all PVC materials before molding, implement advanced venting designs, and fine-tune injection speed and pressure. These measures prevent trapped air and gas, ensuring that every PVC end cap is solid, strong, and long-lasting.

5. Short Shots

Short shots happen when the mold cavity is not completely filled, leaving parts incomplete. This can be caused by low injection pressure, high melt viscosity, cold spots, or poor venting. WITMOLD solves these issues through precise control of injection pressure, shot size, and melt temperature, combined with mold designs optimized for smooth PVC flow. As a result, all end caps and custom components are fully formed, with consistent quality and no missing sections.

6. Flash

Flash is excess material that seeps out along mold parting lines or edges, usually caused by high injection pressure, misaligned molds, or inadequate clamping force. To prevent flash, WITMOLD uses high-precision molds engineered to strict tolerances, along with proper clamping and alignment practices. Regular mold maintenance and inspections further ensure clean, accurate PVC end caps without the need for excessive post-production trimming.

7. High-Quality PVC Injection Molding Practices

Producing defect-free PVC parts requires attention to both material and process. WITMOLD selects high-quality, moisture-free PVC resin, maintains molds regularly, and fine-tunes injection speed, melt temperature, holding time, and cooling for each unique part design. Advanced mold flow simulation and trial runs help predict and prevent defects before mass production, saving time and reducing waste. This holistic approach ensures that every PVC end cap meets the highest standards for durability, aesthetics, and performance.

8. Applications and Advantages of PVC End Caps

PVC end caps are essential components for protecting and sealing pipes, tubes, and other cylindrical products. At WITMOLD, our PVC end caps are widely used across multiple industries, including:

-

Plumbing and Piping Systems: End caps seal pipe ends during storage or transportation, preventing dust, dirt, and moisture from entering.

-

Construction and Industrial Applications: They protect tube ends, fittings, and structural components during fabrication, handling, and installation.

-

Furniture and Equipment Manufacturing: PVC end caps prevent scratches, corrosion, or damage on metal tubes, rails, and other components.

-

Automotive and Mechanical Industries: Custom end caps provide protection for pipes, hoses, and other components in assembly and storage.

Advantages of WITMOLD PVC End Caps:

-

Durable and resistant to impact, chemicals, and environmental conditions.

-

Precise fit for different pipe and tube diameters, ensuring reliable sealing.

-

Customizable designs to meet specific industrial or OEM requirements.

-

Smooth, defect-free surfaces thanks to advanced mold design and optimized injection processes.

By combining superior material selection, precise mold engineering, and strict quality control, WITMOLD PVC end caps deliver both functional reliability and aesthetic quality for a wide range of applications.

Conclusion

PVC injection molding defects such as warping, sink marks, flow lines, bubbles, short shots, and flash can affect the quality and functionality of molded products. Through careful mold design, precise process control, and premium materials, these defects can be minimized or eliminated. At WITMOLD, we specialize in producing high-quality PVC end caps and other custom components with excellent durability, consistent performance, and wide-ranging industrial applications. Our expertise ensures that every product meets the highest standards for both function and appearance.