Inserted molding, also known as insert molding, is a highly efficient and robust manufacturing method in which pre-placed metal or functional components—such as threaded inserts, terminals, or electrical contacts—are encapsulated with plastic in a single molding process. Witmold provides professional inserted molding tool solutions that ensure high reliability, integrated structures, and reduced post-assembly work.

Our Technical Advantages

-

Extensive Experience and Design Expertise

-

Our engineering team understands the critical design principles of insert molding, including insert positioning, supporting structures, cooling channels, and gate design to achieve strong mechanical and structural bonds between the plastic and the insert.

-

We provide DFM (Design for Manufacturing) feedback early in the process to optimize part performance and production efficiency.

-

-

High-Quality Tool Materials and Manufacturing

-

We select premium tool steel and apply proper heat treatments to enhance durability and fatigue resistance.

-

Our molds are precision CNC machined, wire-cut (EDM), polished, and carefully assembled to ensure high accuracy and stability.

-

-

Strict Quality Control

-

Each mold undergoes first-article inspection, trial molding, and dimensional checks to ensure the molded parts meet specifications and the inserts are firmly secured.

-

We retain trial molding data and sample records to support consistent mass production.

-

-

Flexible Production Capability

-

We support both low-volume prototyping and medium to high-volume production.

-

Insert placement can be manual or automated, depending on client requirements, ensuring efficiency and repeatability.

-

-

Reduced Post-Assembly Effort

-

By embedding inserts directly into the plastic, we eliminate additional assembly steps such as screwing, bonding, or mechanical fastening.

-

This one-piece integration enhances product reliability and durability.

-

-

Optimized Material Combinations

-

We combine various plastics with metals or other insert materials to create integrated parts with structural strength and functional performance.

-

Material selection is tailored to meet requirements such as high temperature resistance, fatigue strength, or chemical resistance.

-

Applications and Industries

Our insert molding tools are widely used in industries such as:

-

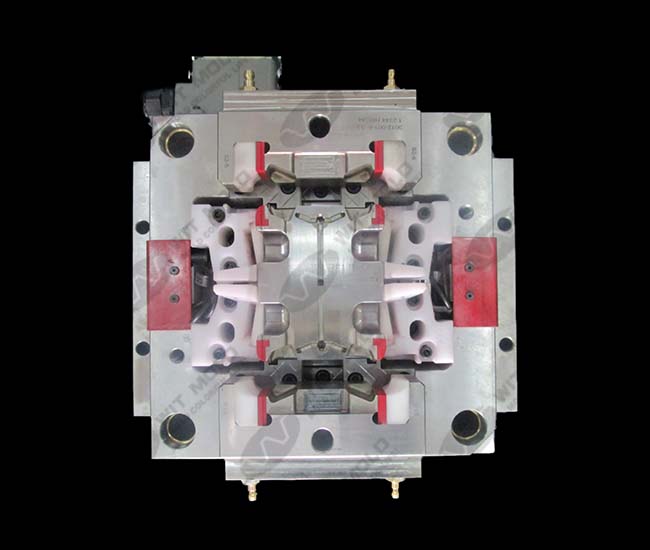

Electronics Connectors and Terminals: Embed metal contacts or terminals into plastic housings for high mechanical stability and reliable electrical performance.

-

Mechanical and Structural Components: Insert threaded nuts, brackets, or support pieces into plastic parts to enhance strength and durability.

-

Automotive Components: Integrate metal inserts in structural parts to reduce assembly time and increase robustness.

-

Medical Devices: Combine metal sensors, connectors, or structural inserts with plastic housings for high performance and durability.

-

Consumer Products: Examples include tools, switches, handles, and fasteners where insert molding improves strength and reliability.

Design and Manufacturing Process

-

Requirement Analysis

-

Receive 3D CAD files or functional specifications for the insert and part.

-

Conduct DFM review, including insert positioning, wall thickness, plastic type, and recommended optimizations.

-

-

Tool Design

-

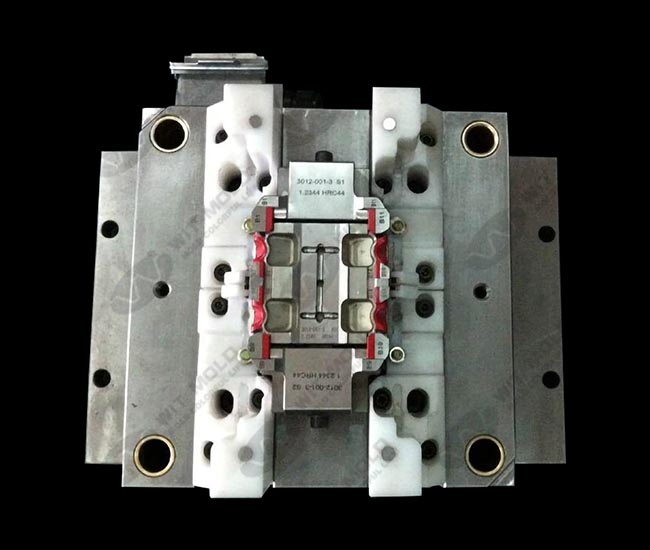

Engineers design the mold structure, including insert fixtures, injection gates, cooling systems, and ejection mechanisms.

-

Flow simulations are used to optimize mold design and prevent defects such as internal stress or warping.

-

-

Tool Manufacturing

-

Select tool steel, heat treat, CNC machine, EDM, polish, and assemble the mold.

-

Integrate insert positioning fixtures, cooling channels, and ejector mechanisms.

-

-

Trial Molding & Validation

-

Conduct trial runs to produce sample parts.

-

Inspect samples for dimensional accuracy, surface quality, and insert stability.

-

Provide trial reports, including first-article inspection and functional testing.

-

-

Mass Production

-

After validation, proceed to small or full-scale production.

-

Monitor tool performance, optimize as necessary, and provide maintenance recommendations.

-

-

After-Sales Support

-

Provide mold maintenance, insert fixture replacement, and wear repair.

-

Optionally, store molds at our facility for on-demand production.

-

Why Choose Witmold

-

Expertise in inserted molding tools for complex structures.

-

High-quality manufacturing standards ensure long-lasting mold and part performance.

-

End-to-end service: design → manufacturing → trial → mass production → maintenance.

-

Collaborative approach: combining your design input with our engineering know-how.

-

Long-term support and mold maintenance for continued reliability.