In modern telecommunications and network infrastructure devices, high-quality plastic components and enclosures are critical for reliable performance. Witmold specializes in High-Precision Injection Molding for Telecommunications Devices, providing customized, efficient, and reliable solutions for everything from individual structural parts to complex assemblies.

Why Work With Us

-

Industry Experience: We have extensive experience in the telecommunications sector, fully understanding the mechanical, environmental, and electromagnetic requirements of telecom equipment.

-

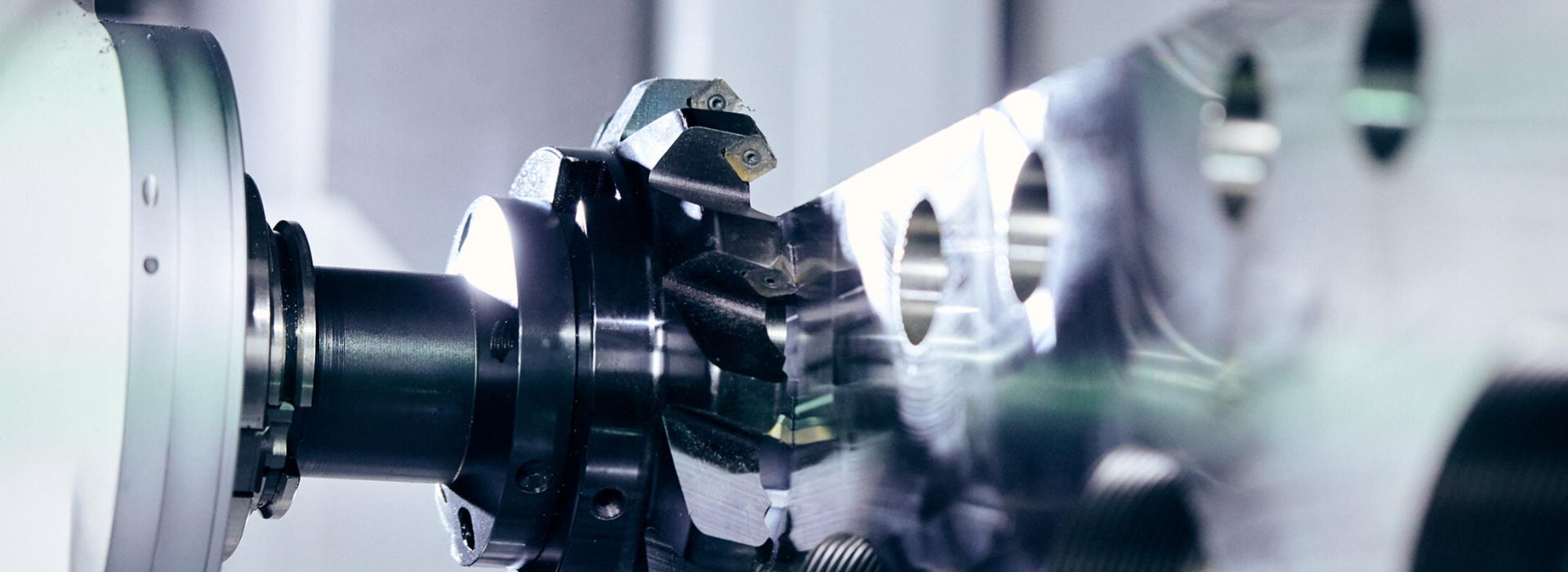

Advanced Technology: Our precision mold design and modern injection molding equipment ensure consistent dimensional accuracy and part quality.

-

Material Expertise: We work with a variety of engineering plastics such as ABS, PC, and LCP, selecting materials that provide durability, heat resistance, and environmental stability.

-

Strict Quality Control: Every component undergoes thorough inspection, from first-article checks to full production verification, ensuring high-precision plastic components and complete enclosures meet exact specifications.

Our Capabilities for Telecommunications and Network Infrastructure Devices

We provide injection-molded parts and enclosures for a wide range of telecom devices, including:

-

Base station antenna radomes and antenna elements

-

Radio device housings

-

Fiber optic splice closures

-

Switch, router, and modem enclosures

-

Patch panels, adapter plates, and network accessories

-

Cable trays, ducts, and brackets for network wiring systems

-

RF-transparent components and Molded Interconnect Devices (MID)

What Sets Us Apart

-

High-Precision Injection Molding

-

Tight tolerances up to ±0.1 mm

-

Optimized mold design to reduce warping and stress

-

-

End-to-End Solutions

-

From mold design and prototyping to batch production

-

Complete enclosures and intricate internal structures delivered ready for assembly

-

-

Material Selection and Customization

-

Engineering plastics chosen for durability, electrical performance, and environmental stability

-

Optional functional additives, such as UV stabilizers or thermal fillers

-

-

Reliability and Durability

-

Designed to withstand harsh outdoor conditions and high operational demands

-

Supports EMC optimization through thoughtful wall thickness, ribs, and support structures

-

-

Flexible Production

-

Capable of small-batch prototypes or large-scale production

-

Mold designs can quickly adapt to evolving telecommunications equipment

-

Benefits to Our Clients

-

Cost Efficiency: Optimized processes reduce scrap and production costs.

-

Faster Delivery: Rapid prototyping and production help bring products to market quickly.

-

Consistent Quality: Reliable components meet demanding operational requirements.

-

Custom Solutions: We can create housings, internal structures, or functional modules tailored to your device design.

-

Long-Term Partnership: We work with OEMs, system integrators, and telecom infrastructure suppliers to support ongoing needs.

Our Process

-

Requirement Review: Discuss device specifications, functional needs, and environmental considerations

-

Material Selection: Recommend plastics suitable for mechanical, electrical, and environmental performance

-

Mold Design: Create high-precision molds with optimized flow and structural design

-

Prototyping: Test dimensional accuracy, tolerances, and environmental suitability

-

Mass Production: Execute large-scale injection molding with strict quality inspection

-

Post-Processing and Assembly: Optional finishing, labeling, or EMI shielding

-

Quality Assurance: Continuous monitoring and reporting to ensure consistent performance

Conclusion

Witmold provides High-Precision Injection Molding for Telecommunications Devices, producing reliable high-precision plastic components and complete enclosures for telecommunications and network infrastructure devices. Whether you require housings, internal structural parts, or functional modules, we offer fully customized, precise, and durable solutions tailored to your equipment.

LET US SUPPLY A QUOTE FOR YOUR NEXT

PROJECT.

Click here to add your own text