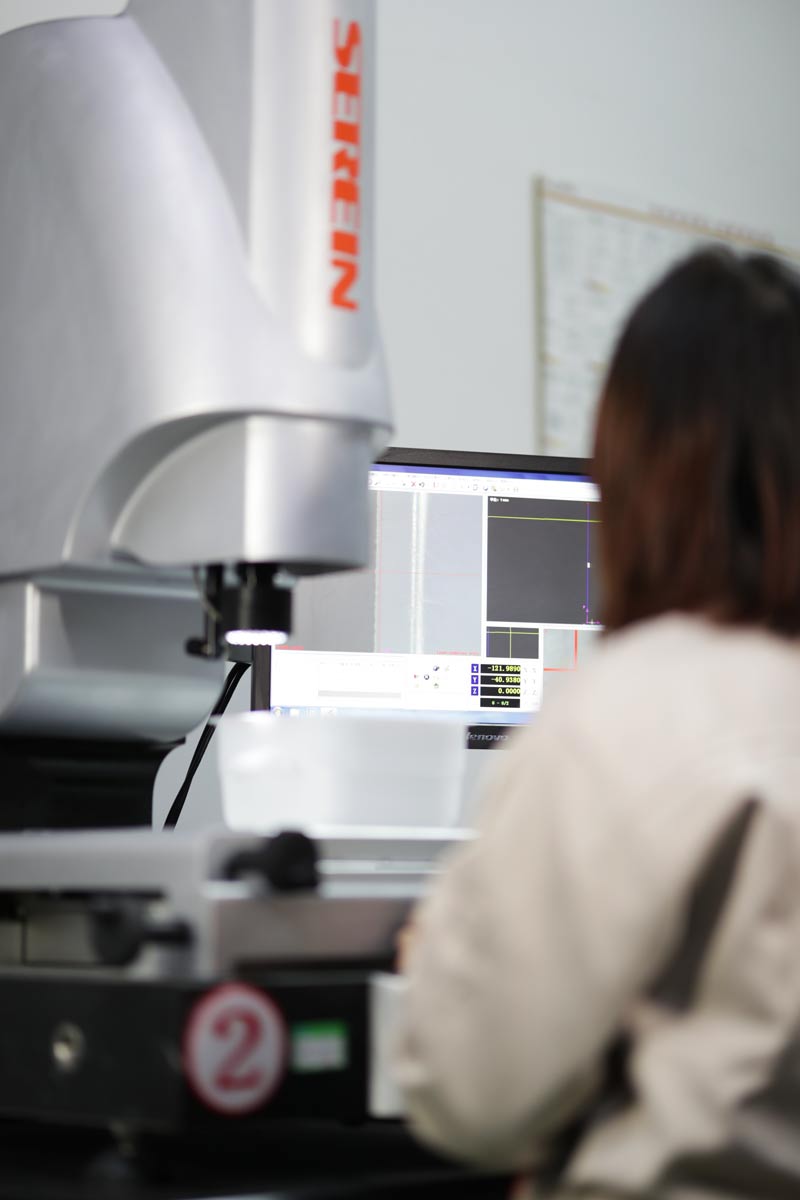

Quality System

WIT MOLD adopts the integrated quality management system and “Three inspections” process, to direct and organize every individual to create high-quality products and services.

Quality is not only implemented by the quality department, but also by every department of the company. Because we know good quality is from the MANUFACTURING process instead of INSPECTION, everyone needs to be responsible for the quality.