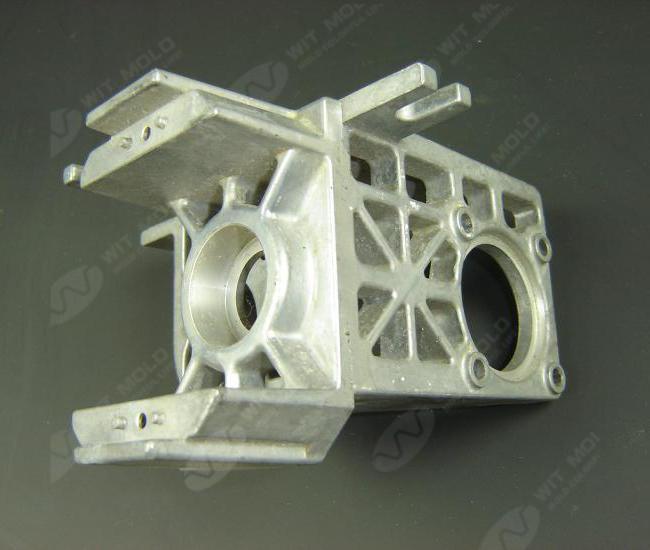

At Witmold, we provide full-scale die casting tooling services to support your metal component manufacturing, especially for high-demand applications. Whether your project requires aluminum, zinc, or other alloy castings, our die casting tools (molds/dies) are engineered for precision, durability, and repeatability.

Why Choose Our Die Casting Tooling Services

-

Rich Tooling Experience

-

Our engineering team has deep experience in die casting mold design and manufacturing. We understand industry requirements for tight tolerances, high cycle life, and consistent performance.

-

We provide seasoned DFM (Design for Manufacturing) feedback based on your part geometry, wall thickness, and functional requirements.

-

-

Advanced Design & Engineering

-

We design molds considering the parting surface, runner system, overflow, venting, cooling channels, and ejector mechanisms to optimize casting performance.

-

Use of simulation tools (e.g., mold flow analysis) helps minimize defects such as porosity, cold‑shuts, and shrinkage.

-

-

High-Quality Tool Materials

-

We use high-grade tool steel (such as H13, Dievar, or other tool steels) to ensure long mold life and stable performance under high-pressure die casting processes.

-

Proper heat treatment processes ensure that mold inserts can resist thermal fatigue and mechanical wear.

-

-

Precision Machining

-

Our tooling is CNC machined, EDM (wire-cut) processed, polished, and assembled under strict quality guidelines.

-

We control dimensional tolerances tightly to ensure your die cast parts come out to spec quickly and consistently.

-

-

Robust Quality Assurance

-

From first-article inspections, material certification, to in-process checks, every tool goes through rigorous validation.

-

We also conduct trial runs and small-batch production to test tool performance before full-scale deployment.

-

Final inspection includes dimensional checks, and we archive trial-molding data for traceability.

-

-

Flexible Production Capability

-

Whether your need is low-volume prototyping or high-volume production, we can scale.

-

We support single-cavity as well as multi-cavity tooling to match production demands and optimize per-part cost.

-

Fast turnaround for prototype tools: once the design is approved, we move quickly into mold build and trial.

-

-

Comprehensive Service

-

One-stop service: mold design → mold manufacturing → trial casting → handover or part production.

-

We also offer post-mold services: polishing, texturing, surface treatment, and maintenance planning.

-

Typical Applications & Industries

Our die casting tooling is suited for a wide range of industries and applications, such as:

-

Automotive components (engine housings, structural parts)

-

Consumer electronics enclosures

-

Industrial machinery parts

-

Lighting fixtures and housings

-

Telecommunications hardware

Because we design for manufacturability from the start, we help clients reduce the need for secondary machining and lower their overall costs while ensuring robust tool life.

Our Tooling Process — How We Work with You

-

Inquiry & Requirement Analysis

-

You provide your part drawings (3D CAD, STEP, etc.) or functional descriptions.

-

We perform a DFM review: assess part geometry, wall thickness, tolerances, and propose design optimizations.

-

-

Tool Design Phase

-

Our engineers create detailed 2D/3D mold designs, including runner system, cooling, and ejector layouts.

-

We simulate the casting process to predict and prevent common defects.

-

-

Tool Manufacturing

-

Select appropriate tool steel, heat-treat, machine cores and cavities using CNC, EDM, polishing.

-

Assemble mold base, inserts, cooling lines, and other components.

-

-

Trial Casting & Validation

-

Conduct trial runs to produce sample castings.

-

Inspect the first articles for dimensional accuracy, surface quality, and mechanical behavior.

-

Provide test reports and trial-molding data for traceability.

-

-

Small Batch / Mass Production

-

Once the trial is validated, we proceed to small batch or full-scale production.

-

Monitor tool performance over cycles, optimize as needed, and provide maintenance recommendations.

-

-

Delivery & Support

-

Deliver the mold to you (or keep it in our facility if agreed).

-

Provide maintenance schedule and support for tool repairs, insert replacements, or rework if needed.

-

Why Partner with Witmold

-

We combine precision tooling expertise with a customer-focused mindset.

-

We emphasize collaboration: your input, our engineering, real-time feedback, and transparent reporting.

-

We commit to long-term tool support and maintenance, ensuring your die casting tools remain productive and reliable.

-

With our global capabilities, we can support you no matter where your production or shipping needs lie.

LET US SUPPLY A QUOTE FOR YOUR NEXT

PROJECT.

Click here to add your own text