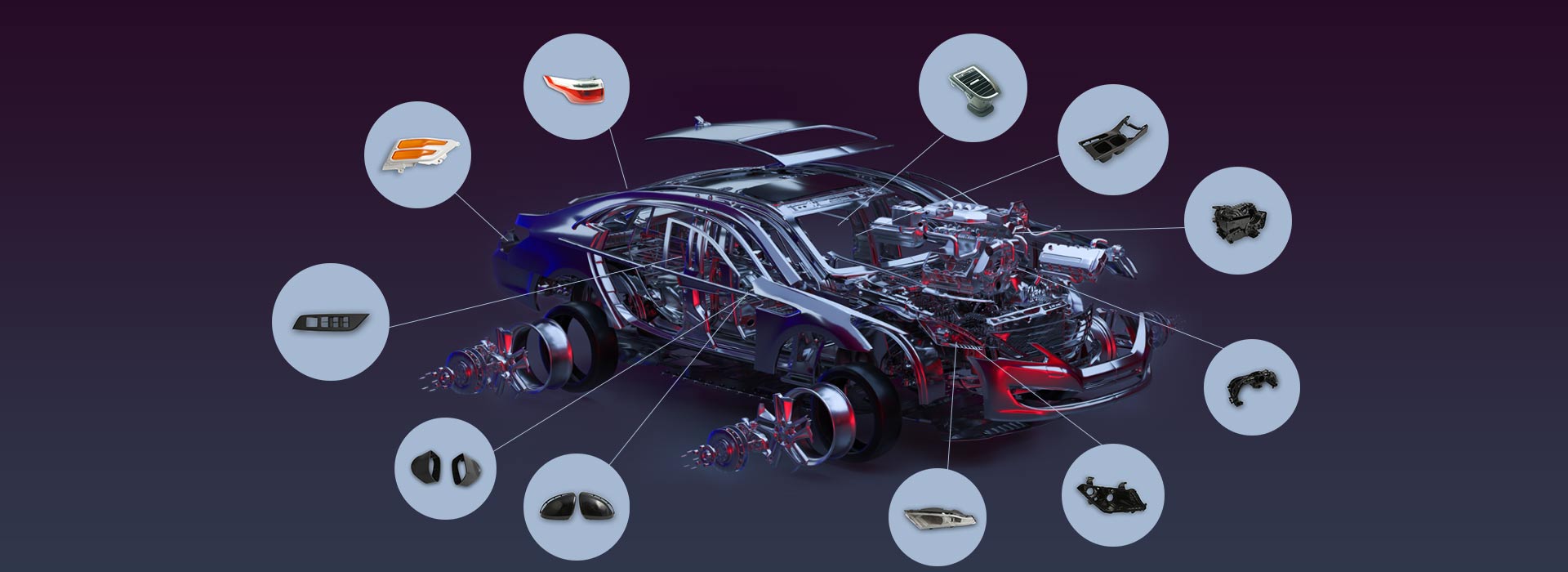

Automotive Injection Mold and Plastic Parts Molding

WIT MOLD serves automotive and parts customers worldwide and over 10 years of experience allows the WIT MOLD team to provide customers with fast development times and consistent quality to ensure that new projects run well.

WIT MOLD engineers will analyze the fill to get the best gate position for optimal flow and design the best cooling channels to ensure minimal package distortionWe have a very good We have a very good injection operator to help set the best injection parameters to avoid any wasted development time and improve the reliability of molding parameters.

In the automotive industry, automotive injection molding plays a critical role in producing high-quality components. Automotive plastic injection molding is widely used to create durable and precise parts, making injection molding automotive a key process in manufacturing. Companies specializing in automotive plastic molding provide essential services for car manufacturers, with many automotive injection molding companies offering specialized solutions. The production of plastic injection molding automotive parts ensures that vehicles are built with reliable and cost-effective components. Whether it’s injection molding automotive parts or working with automotive plastic injection molding companies, the focus is on delivering excellence. Injection moulding automotive parts and injection molded plastic auto parts are essential for creating everything from small fittings to large body components. The expertise in automotive mold design and production is what drives innovation and quality in the automotive sector.

Automotive plastic injection molding

Bumper, dashboard parts, air intake grille, wing, radiator grille, trim, engine parts, water tank parts, air conditioning parts, air filter parts, various water bottles, seat parts, floor parts, roof parts, bar parts, steering wheel parts, door trim, rear view mirror and various fasteners, front and rear lights, etc.

Automotive Injection Molds Manufacturer & Custom Car Plastic Mold Supplier

Witmold specializes in the design and production of high-precision automotive injection molds, providing comprehensive tooling solutions for both interior and exterior car components, as well as under-the-hood parts and EV systems. As a trusted automotive mold supplier in China, we deliver reliable molds with high dimensional accuracy, long service life, and rapid cycle times.

Automotive Interior Plastic Molds

Our expertise covers a wide range of car interior plastic molds, designed for performance, aesthetics, and easy assembly. Products include:

- Car dashboard mold manufacturer

- Door panel injection mold

- Automotive console molding specialist

- Car seat component molds

- Automotive cup holder molds

- Interior LED light housing molds

We also offer specialist solutions for high-gloss interior mold finishes, Class A surface car molds, and low-warpage automotive tooling, ensuring the highest standards for visible interior parts.

Automotive Exterior Plastic Molds

Witmold offers durable and precise automotive exterior plastic molds that are engineered to withstand UV exposure, mechanical wear, and harsh environments. Our product range includes:

- Car grille mold manufacturer

- Mirror housing molds for vehicles

- Fender plastic tooling

- Exterior trim injection molds

All molds are custom-built for fast cycles, consistent quality, and seamless fit with OEM specifications.

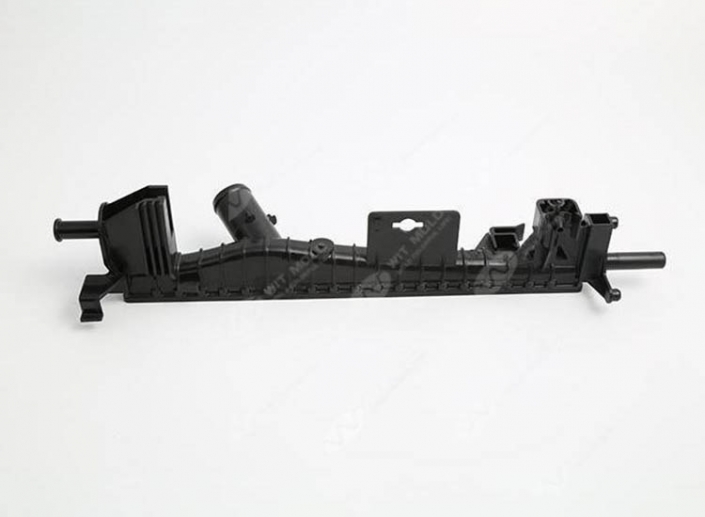

Under-the-Hood & EV Component Molds

We support the growing demand for high-performance under-the-hood plastic parts and EV battery system components. Our advanced tooling services include:

- EV battery housing molds

- Engine compartment plastic molds

- Air intake manifold molds

- Fuel system component molds

- Charging port cover molds

These molds are engineered to meet thermal, structural, and chemical resistance requirements for modern engine bays and electric vehicle platforms.

Full-Service Automotive Mold Supplier

As a professional automotive mold supplier in China, Witmold is committed to delivering top-tier automotive injection molds tailored to your design, material, and production needs. From concept to final tooling, our experienced team ensures the success of every mold project.

Contact us to learn more about how we can support your automotive manufacturing with precision-molded plastic solutions.

Automotive Interior Instrument Panel Assembly

INSTRUMENT PANEL

AIR CONDITION OUTLET

CENTER CONSOLE PANLE

COMBINATION DASHBOARD SHIELD

GLOVEBOX

Automotive Side Interior Garnish Assembly

A PILLAR UPPER GARNISH

B PILLAR UPPER GARNISH

C PILLAR UPPER GARNISH

A PILLAR LOWER GARNISH

B PILLAR LOWER GARNISH

REAR SILL GARNISH

FRONT SILL GARNISH

Automotive Door Panel Assembly

INNER BELTLINE WEATHERSTRIPER

MAP POCKET

ENERGY-ABSORBING BUFFER BLOCK

TRIANGLE GARNISH

UPPER GARNISH

LOW SUBSTRATE

DOOR TRIM

ABACULUS BOARD

SWITCHPLATE

INNER PULL CUP

ARMREST

Automotive Front & Rear Bumper

UPPER GRILLE

FOGLAMP

BUMPER

CUSHION FOAM

SNAP R/L

LOWER GRILLE